CUTTING NOZZLE AMD, HIGH SPEED

Group Number: 2551AMD is special acetylene high speed mixing cutting nozzle with modern high performance cutting oxygen channel to be used with machine cutting torch BGR™/X541. Both cutting and heating nozzles are chrome plated. 2-piece design, simple cleaning procedure, COOLEX® inside increases the lifetime of the product and safety of operation. Both cutting and heating nozzles are delivered assembled as one item. The package contains 1 piece.

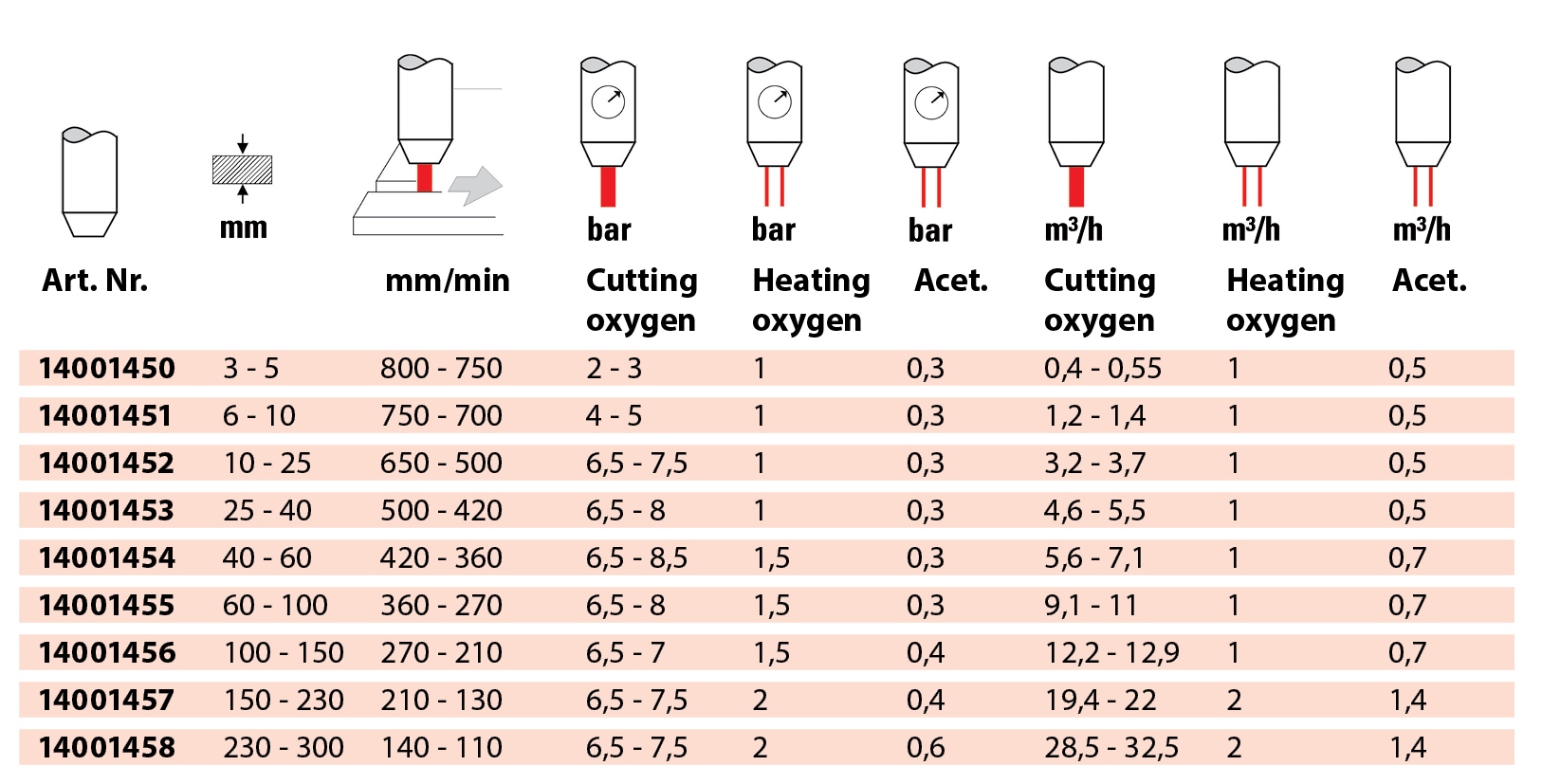

| Art. Nr. | Type | Cutting range (mm) |

| 14001450 | Cutting nozzle | 3 - 5 |

| 14001451 | Cutting nozzle | 6 - 10 |

| 14001452 | Cutting nozzle | 10 - 25 |

| 14001453 | Cutting nozzle | 25 - 40 |

| 14001454 | Cutting nozzle | 40 - 60 |

| 14001455 | Cutting nozzle | 60 - 100 |

| 14001456 | Cutting nozzle | 100 - 150 |

| 14001457 | Cutting nozzle | 150 - 230 |

| 14001458 | Cutting nozzle | 230 - 300 |

GENERAL CONDITIONS FOR HIGH QUALITY AND EFFICIENT CUTTING

GCE machine cutting nozzles are designed to reach the cuts of quality level 1 according to EN ISO 9013. It is possible to reach maximal cutting speed by setting-up recommended cutting parameters of particular nozzles shown below, cutting of straight cuts, by using of clean metal sheet surface, oxygen with purity 99,5 % or better. Correct values of gases pressures are to be measured at the torch inlet. Parameters are prepared for mild steel with maximal carbon content of 0,25 %. Quality cutting machine with proper gaas supply system, original GCE cutting equipment and new, undamaged, original cutting and heating nozzles are to be applied.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)