MULTISTAGE (S2+)

- GCE multi-stage regulators are designed to provide accurate, fluctuation free delivery for precision applications such as shielding gas arc welding, CNC oxy-fuel cutting or laboratory use.

- The first stage reduces the inlet pressure by over 90% and the large second stage diaphragm ensures accurate delivery pressure.

- GCE multistage regulators are precision built to latest EN ISO 2503 and

EN ISO 7291 standards to provide maximum accuracy and safety. - These regulators have the additional feature of being able to pipe away gases from the relief valve port, and comply with the stringent requirements of EN ISO 7291 even for strict manifold application.

FEATURES, ADVANTAGES, BENEFITS

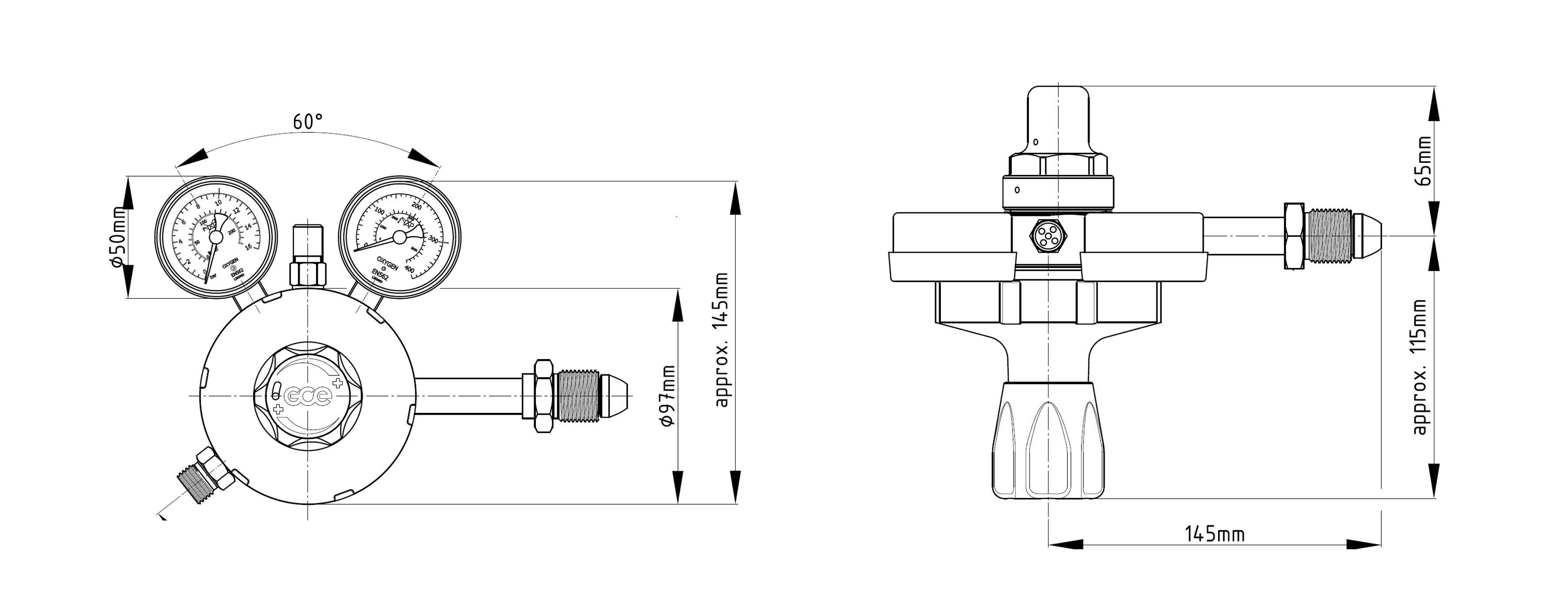

- Top-safe & Accurate Bulkhead 50mm Gauges

- Body and 1st. bonnet forged from high-quality Brass

- Technical Data permanently marked on body

- Powder-painted surface for high corrosion resistance

- Non-adjustable safety valve located on top side of body

- Inlet Connections exactly complying with BS-341 Standards

- Max. Outlet pressure locked for operational safety

- Non-detachable Ergonomic Plastic control knob

TECHNICAL DATA

| Body: | Forged Brass, chemically stabilized and gold powder-painted |

| First stage Bonnet: | Forged Brass, chemically stabilized and powder painted |

| Second stage Bonnet: | Die-cast Zinc alloy, chemically stabilized and powder painted |

| First stage Diaphragm: | Diam. 40 mm, pre-shaped stainless steel |

| Second stage Diaphragm: | Diam. 82 mm EPDM fabric-reinforced rubber |

| Encapsulated Valve: | Brass body sealed by PA (first stage) or high-grade chloroprene rubber (second stage) |

| Pressure Gauges: | Safe design, bulkhead 50mm gauges, dual scales, accuracy class 2,5% |

| Inlet Stem & Nut: | High-tensile brass, geometry complying to BS-341 standard |

| Safety Valves: | On both regulator stages, non-adjustable |

| Control elements: | Plastic handwheel + captive pressure adjusting screw |

| Setting: | Ergonomic PA handwheel, adjustable limitation of P2 max |

.jpg)

.jpg)

.jpg)