X21® Original

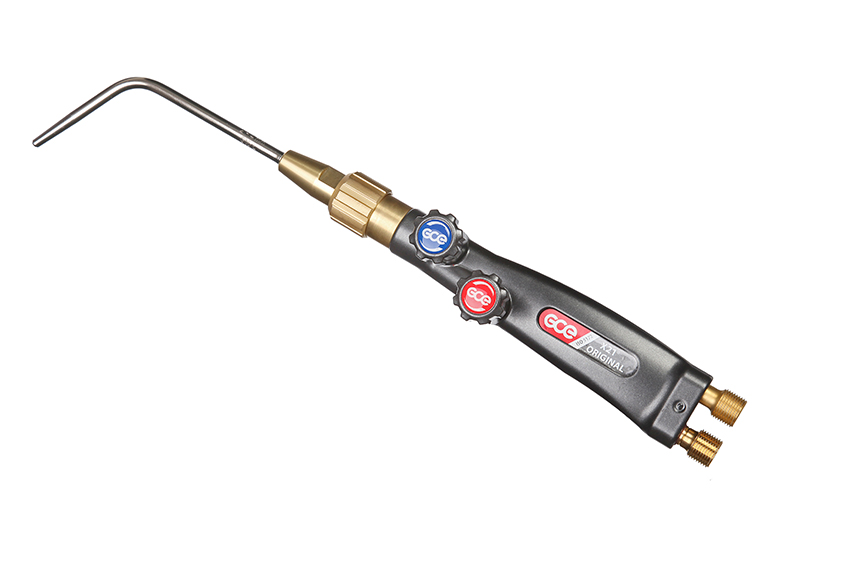

The GCE X21® Original with large capacity for welding, cutting, soldering, heating and straightening. X21® Original is a combined gas welding and gas cutting torch for manual work. It is a pressure torch (II) that is designed on the basis of the stringent demands stipulated by standard EN ISO 5172.

X21® is a versatile and complete torch system, with cutting attachments for injector or pressure principle, and with round or oval shank, for all medium and heavy duty cutting, welding, and heating jobs. With the pressure principle, you use 3-cone cutting nozzles, with the injector principle you use flat seal cutting nozzles. The choice is yours. All X21® equipment fully meets the requirement of EN ISO 5172 and is manufactured at our factory under the Quality Management System ISO 9001.

X21® CAN BE USED IN THE FOLLOWING OPERATIONS

- Welding in thicknesses up to 14 mm

- Cutting in carbon steel in thicknesses up to 500 mm, circle cutting, hole cutting, bevel cutting, and rivet washing

- Braze welding

- Brazing

- Heating, bending, and straightening

- Gouging

- Flame cleaning

- Flame straightening

X21® ORIGINAL

X21® satisfies the high expectations that users have of a quality torch. With the X21® pressure torch, the gases are mixed in the torch head, which increases safety against flashbacks. Pressure torches entail that Oxygen and fuel gas for the heating flame have the same inlet pressure to the nozzle. X21® Original is available for the fuel gases Acetylene and Propane (LPG). Using Propane as the fuel gas, all the processes apart from gas welding can be used.

BENEFITS WITH X21® ORIGINAL

- Choose between round and oval torch handle

- Colour marking: red for fuel gas and blue for Oxygen on the handle and cutting attachment

- Potential to weld material thicknesses up to 14 mm

- Cut up to 500 mm

- Heat for straightening and heat forming

- Special flame-straightening torches

- Flame-cleaning torches

- Large range of accessories

- Suitable for powder cutting

X21® FOR WELDING

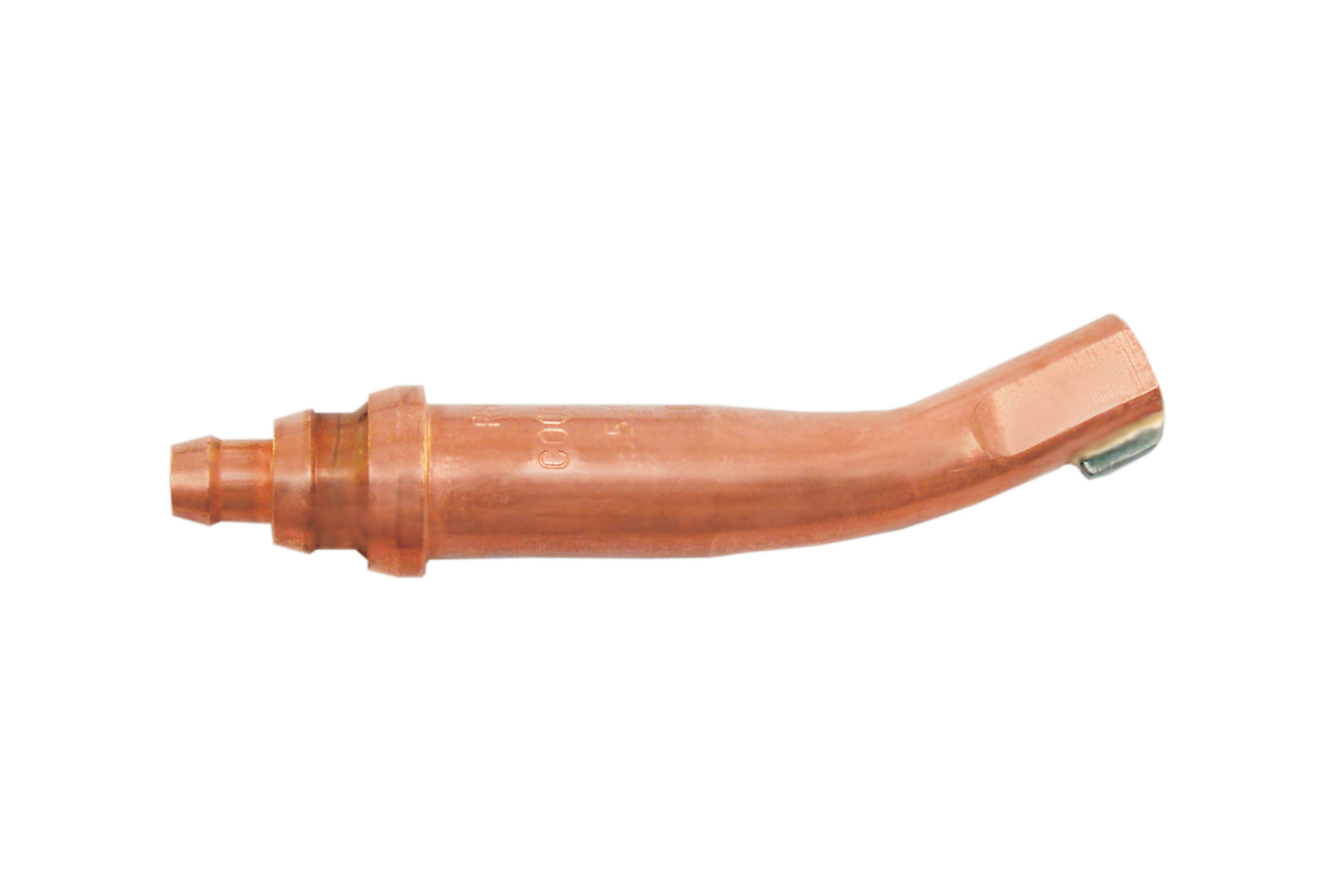

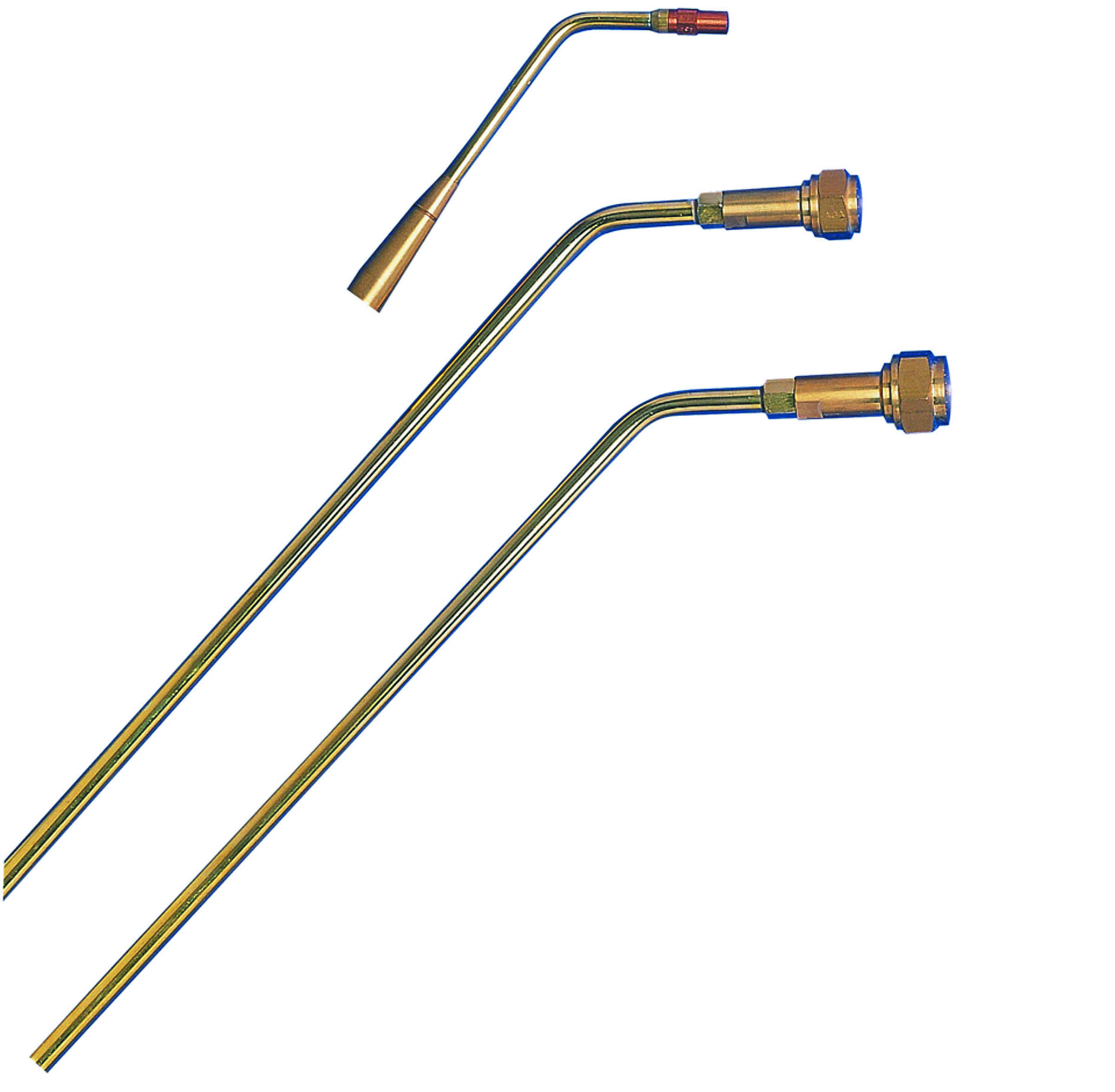

The welding attachments, 8 inserts from 40 1250 l/h, are entirely forged from copper with deflect weld spatter. For weld locations that are difficult to access, here are four flexible welding attachments, ranging from 80 to 500 l/h, that are not chrome-plated. All welding attachments have replaceable welding nozzles.

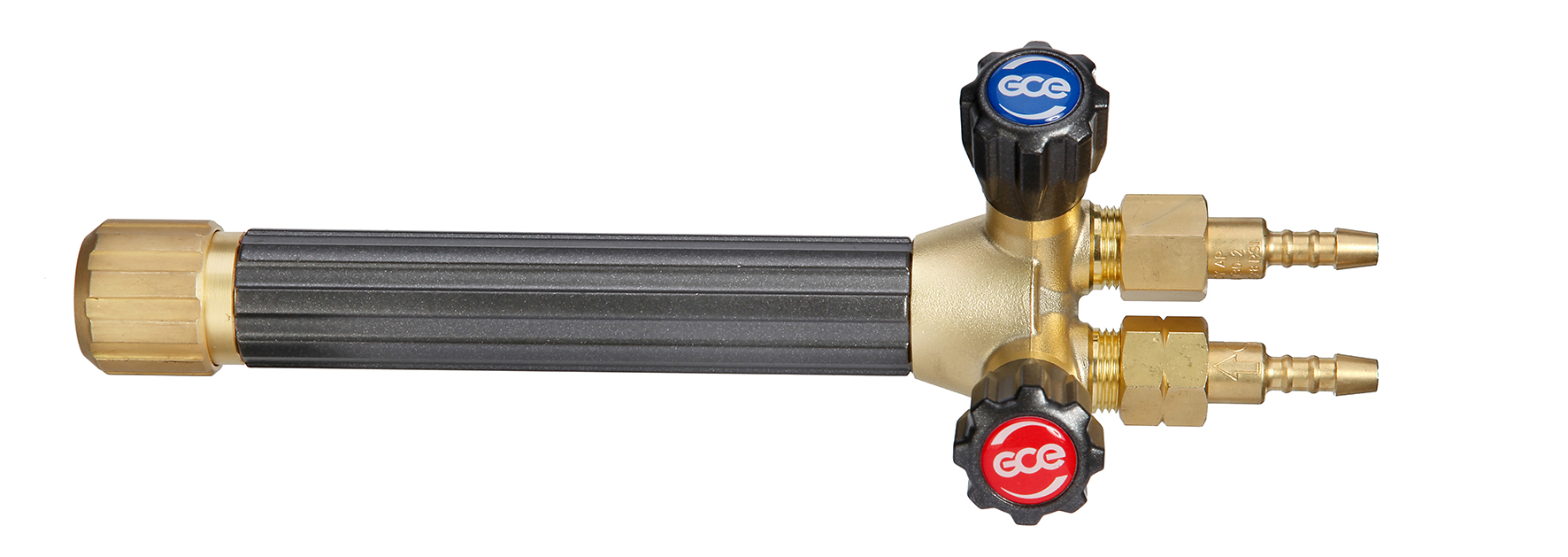

AVAILABLE SHANK TYPES

1) ROUND TYPE

| 0764658 | SHANK | G3/8 + G3/8 LH (hose nipples 6,3 mm) |

| 0767946 | SHANK | G3/8 + G3/8 LH (BV12 - 6,3 mm) |

2) FLAT TYPE (OVAL)

![]()

| 0763939 | SHANK | G3/8 + G3/8 LH |

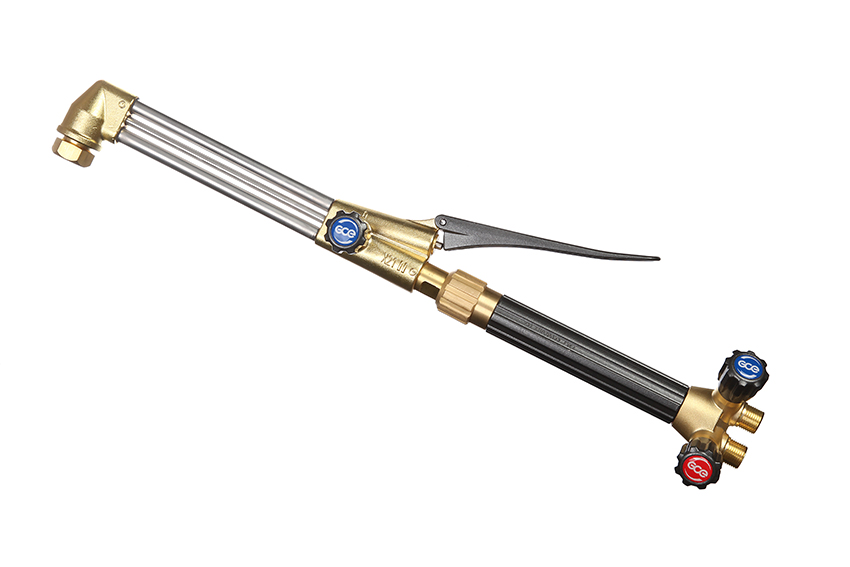

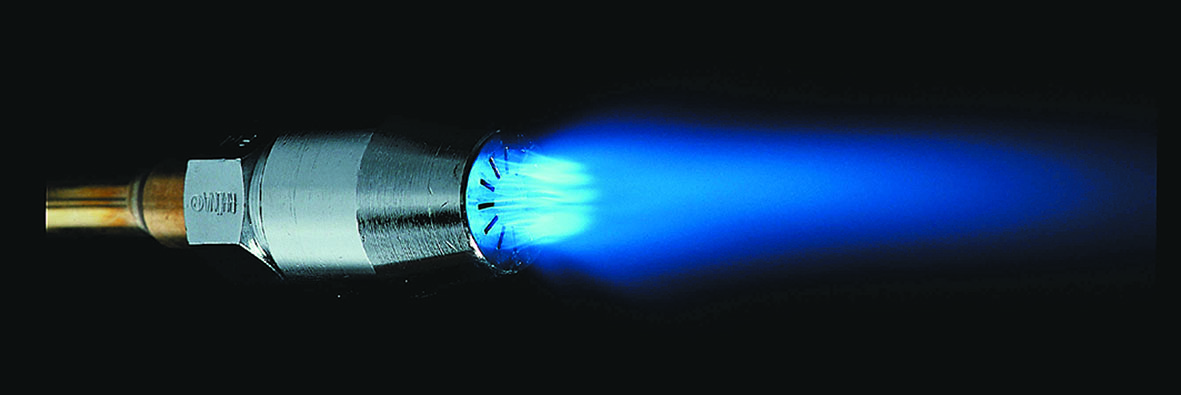

X21® FOR CUTTING NOZZLE MIX

X21® Original for cutting:

- Cutting attachment with a lever valve or wheel valve

- Acetylene or Propane

- Nozzle mount 90°, 75°, 45° and 0°

- Material thicknesses up to 500 mm

- Several different series of 3-cone sealed cutting nozzles

- Various alternative gouging nozzles

- Rivet cutting nozzles

- Available both as injector and pressure torches

CUTTING ATTACHMENT

STANDARD SIZE

![]()

![]()

| Art. Nr. | Control | Heating gas | Type | Head angle | Length (mm) |

| 0766261 | Knob | Ace/Prop | Nozzle MIX | 90° | 238 |

| 0766263 | Butterfly | Ace/Prop | Nozzle MIX | 90° | 238 |

| 0764574 | Lever | Ace/Prop | Nozzle MIX | 90° | 239 |

| 0766264 | Butterfly | Ace/Prop | Nozzle MIX | 75° | 242 |

| 0764575 | Lever | Ace/Prop | Nozzle MIX | 180° | 267 |

| 0767941 | Lever | Ace/Prop | Nozzle mix | 90° | 319 |

| 0764561 | Lever | Ace/Prop | Nozzle MIX | 75° | 322 |

| 0764560 | Lever | Ace/Prop | Nozzle MIX | 45° | 340 |

| 0764559 | Lever | Ace/Prop | Nozzle MIX | 180° | 347 |

| F22310035 | Lever | Ace/Prop | Nozzle MIX | 75° | 795 |

X21® FOR WELDING

WELDING ATTACHMENT OXYGEN-ACETYLENE

![]()

| Art. Nr. | Size Nr. | Gas flow (l/h) | Thickness (mm) |

| 9389430P | 0 | 40 | 0,2 - 0,5 mm |

| 9389440P | 1 | 80 | 0,5 - 1,0 mm |

| 9389450P | 2 | 160 | 1,0 - 2,0 mm |

| 9389460P | 2E | 230 | 2,0 - 3,0 mm |

| 9389470P | 3 | 315 | 2,0 - 4,0 mm |

| 9389480P | 3E | 400 | 3,5 - 5,0 mm |

| 9389490P | 4 | 500 | 4,0 - 6,0 mm |

| 9389500P | 4E | 650 | 5,0 - 7,0 mm |

| 9389510P | 5 | 800 | 6,0 - 9,0 mm |

| 9389520P | 5E | 1000 | 7,0 - 10,0 mm |

| 9389530P | 6 | 1250 | 9,0 - 14,0 mm |

X21® FOR POWDER CUTTING

| Art. Nr. | Lenght | Head angle |

| F22310035 | 655 mm | 75° |

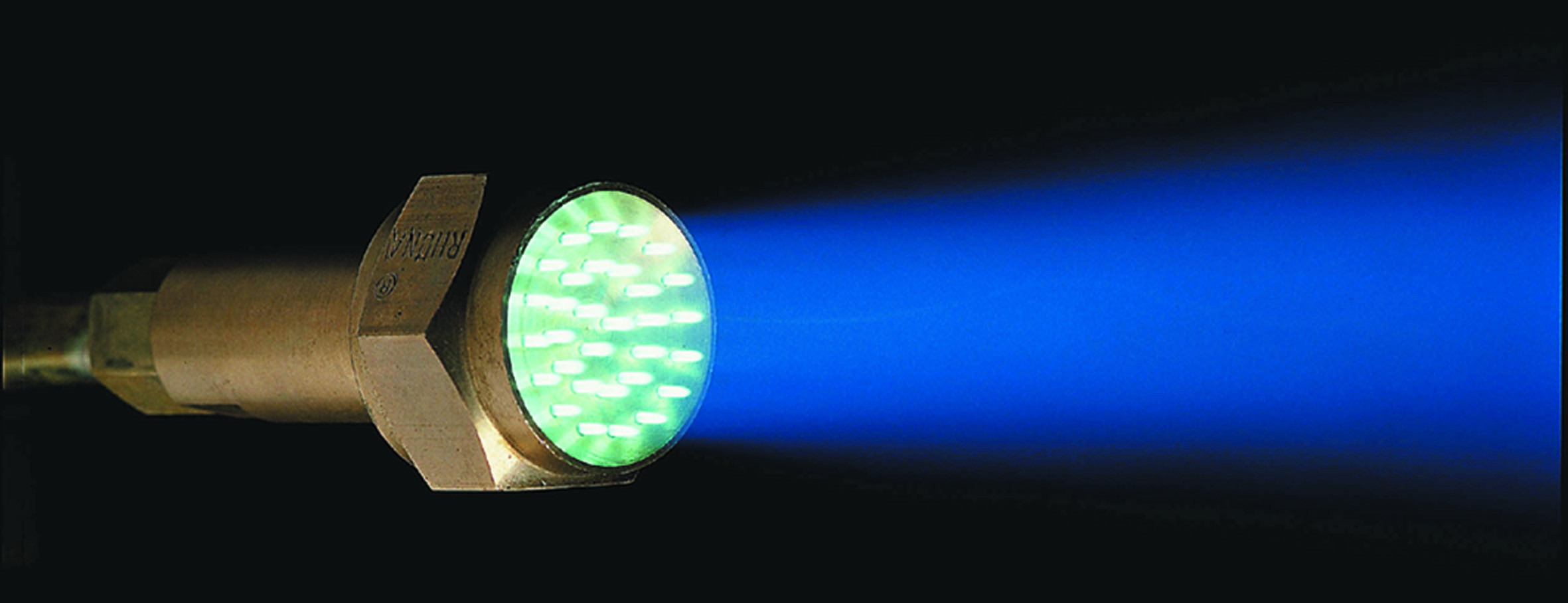

X21® FOR HEATING

In addition to various welding attachments, there are three single flame heating attachments for Acetylene, ranging from 1800 to 5000 l/h, as well as three multiple flame heating attachments ranging from 1000 to 5000 l/h. In addition, there are four multiple flame heating attachments for Propane, ranging from 1000 to 7000 l/h.

HEATING ATTACHMENT, SINGLE FLAME

OXYGEN-ACETYLENE

![]()

| Art. Nr. | Size Nr. | Working pressure Oxygen (bar) |

Working pressure |

| 9389540P | 1800 l/h | 3 | 0,3 |

| 9389550 | 2500 l/h | 6 | 0,4 |

| 219100228 | 5000 l/h | 8 | 0,6 |

HEATING ATTACHMENT, MULTIFLAME

OXYGEN-ACETYLENE

| Art. Nr. | Size Nr. | Working pressure Oxygen (bar) |

Working pressure Acetylene (bar) |

| 202232210 | 1000 l/h | 3 | 0,3 |

| 202232211 | 2500 l/h | 6 | 0,4 |

| 202232212 | 5000 l/h | 8 | 0,6 |

HEATING ATTACHMENT, MULTIFLAME

OXYGEN-PROPANE

| Art. Nr. | Size Nr. | Working pressure Oxygen (bar) |

Working pressure Propane (bar) |

| 202232217 | 1 000 l/h | 0,9 | 0,7 |

| 202232218 | 2 000 l/h | 2,4 | 0,8 |

| 202232219 | 4 000 l/h | 4,9 | 1,9 |

| 202232220 | 7 000 l/h | 8,0 | 2,5 |

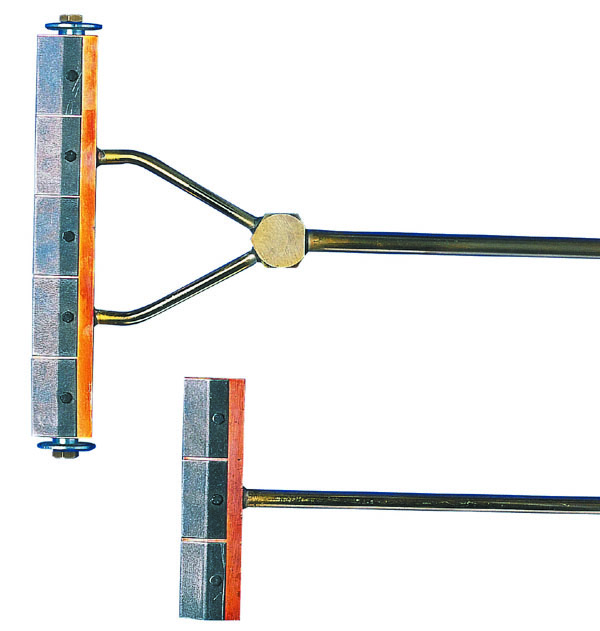

X21® FOR FLAME STRAIGHTENING

ACETYLENE

![]()

| Art. Nr. | Type | Working pressure Oxygen (bar) |

Working pressure Acetylene (bar) |

Length (mm) |

| 14070514 | 3 nozzles | 7 | 0,7 | 730 |

| 202232267 | 5 nozzles | 7 | 0,7 | 690 |

X21® FOR FLAME CLEANING

ACETYLENE

| Art. Nr. |

Width of head |

Working pressure Oxygen (bar) |

Working pressure Acetylene (bar) |

| 202235735 | 50 | 3 | 0,7 |

| 202235736 | 150 | 5 | 0,7 |

| 202235731 | 250 | 5 | 0,8 |

CUTTING NOZZLES HP337 FOR POWDER CUTTING

| Art. Nr. | Thickness (mm) |

Gas | Working pressure Oxygen (bar) |

Working pressure Propane (bar) |

| 14001276 | 0 - 50 | Propane | 5 | 1 |

| 14001277 | 50 - 100 | Propane | 7 | 1 |

| 14001278 | 100 - 200 | Propane | 8 | 1 |

| 14001279 | 200 - 300 | Propane | 12 | 1 |

POWDER ATTACHMENT

| Art. Nr. | Lenght |

| 14030002 | 815 mm |

| Art. Nr. | Description | Position |

| 14030004 | Powder nozzle | 1 |

| 14030003 | Powder head with neck | 2 |

| 14030007 | Clamp | 3 |

| 14030006 | Ball valve | 4 |

| 14030005 | Tube with fittings | 5 |

| 14099611 | Hose nipple 6,3×G3/8" | 6 |

| 14099672 | Nut G3/8" | |

| IPF2007 | Iron powder feeding |

X21® ACCESSORIES

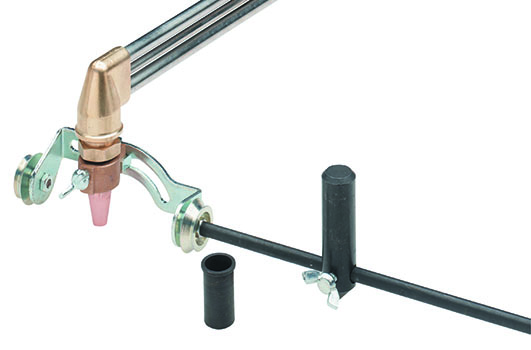

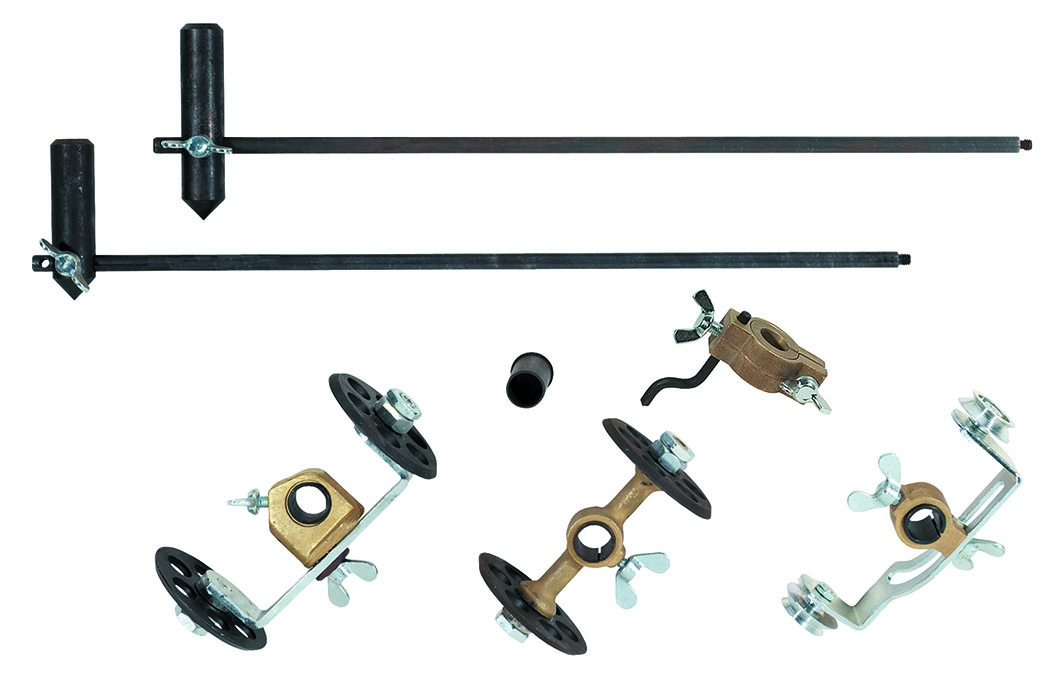

| Art. Nr. | Description | Position |

| 219100280 | Radius arm with centre point, big wheel | 1 |

| 548219100297P | Radius arm with centre point, small wheel | 2 |

| 202130143 | Hole cutting attachment | 3 |

| 219100296 | Twin wheel cutting guide, big wheels for bevel cutting | 4 |

| 548219100295 | Twin wheel cutting guide, big wheels | 5 |

| 214100454 | Twin wheel cutting guide, small wheels | 6 |

| 548219100509 | Bushing | 7 |

Additional Downloads for this Product

.jpg)