APC (AUTOMATED PROCESS CONTROL)

FIT+ CATALOGUE

FIT+ CATALOGUE

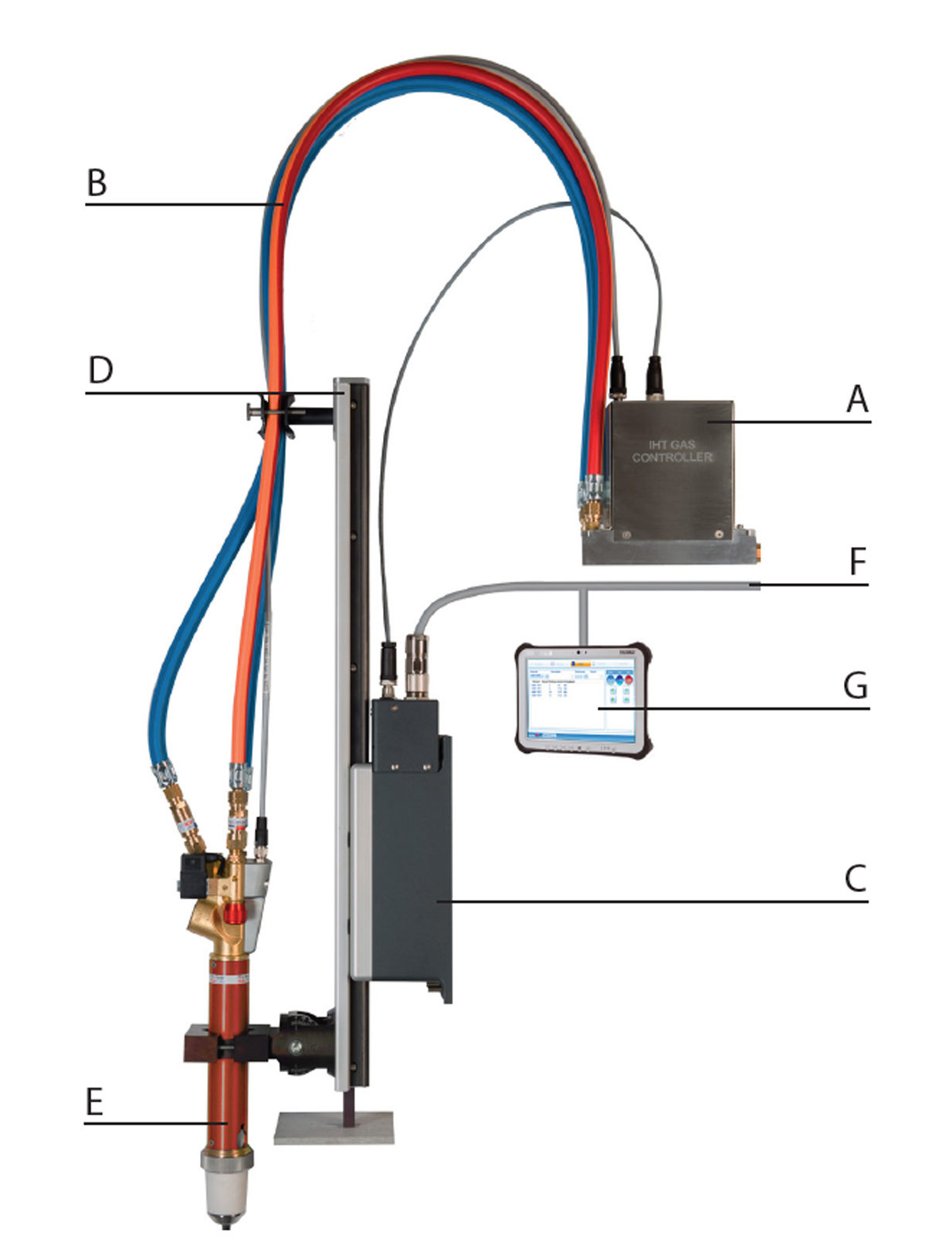

APC O3M Automatic Process Control with Operator Terminal

- Cutting database for FIT+ three torches is stored in Operator Terminal

- APC operator interface is integrated into Operator Terminal

- Hassle free interface to CNC, only "Start Process" from CNC and "Ok to Move" from APC required

- Optional "Change Speed" output to CNC for piercing process and reduce speed while moving over slag

- Operator Terminal is based on 10" Windows Tablet

- Operator Terminal Software can run on any Windows 7 or higher Operating Software

APC C3M Automatic Process Control, Operator Interface integrated into CNC

- Cutting database for FIT+ three torches are implemented in machine control (CNC)

- APC operator interface is embedded in CNC

- APC with flexible fieldbus interface to connect to CNC (e.g. Modbus)

- Hassle free interface to CNC, only "Start Process" from CNC and "Ok to Move" from APC required

- Optional "Change Speed" output to CNC for piercing process and to reduce speed while moving over slag

BENEFITS

- Higher productivity using best embedded cutting process

- Consistent cutting quality using fully automatic process

- Lower installation cost through fully integrated system

- Highest cutting quality and productivity by using best components

FEATURES

- Cutting process and database is integrated into APC system

- Oxy-Fuel Cutting System with Cutting Torch, Gas Control,

- Ignition, Height Sensing and Lifter all in one package

- Fits on all carriages

- Only requires oxygen and fuel gas connection

- Gas hoses, valves, flash back arrestors are part of the package

- Gas Controller mounted close to the torch

- Works with all common CNC controllers on the market

- Modular approach allows highest flexibility

- Setting torch height in mm or inch

- One Gas Controller per torch

APPLICATION FIELDS

- Oxy-Fuel cutting machines for straight cutting of up to 300 mm sheets

- Single or multi torch applications, one Gas Controller per torch

- 100 % compatible with the IHT M 4000 PCS and

M 4000 BAS plasma systems - Cut sheets up to 100 mm thickness when used with active height sensor and up to 300 mm with Splash Protector

CNC CONNECTIONS

- In: Start Process

- In: Manual Up / Down

- In: Clearance Control Off

- In: Calibrate

- Out: Ok to Move

- Out: Change Speed

- Out: Error/Collision

- Fieldbus

- Power: 24 V DC

| Item No. | Description | APC O3M |

APC C3M |

Position |

| 140800 | Gas Controller | ☑ | ☑ | A |

| 140801 | Gas Hose Assembly (1,5 / 2,0 / 2,5 m) | ☑ | ☑ | B |

| 140802 |

M 4000 APC Basic Kit (Body, CU+, DIG Cable, Power Supply) |

☑ | ☑ | C |

| 140810 | Guiding rail kit APC 220+ mm | ☑ | ☑ | D |

| 140811 | Guiding rail kit APC 350 mm | ☑ | ☑ | D |

| 140812 | Guiding rail kit APC 500 mm | ☑ | ☑ | D |

| 140110 |

Sensor Torch FIT+ three 220/45PMY DIG (Propane cutting torch with digital torch controller) |

☑ | ☑ | E |

| 140111 |

Sensor Torch FIT+ three 220/45A DIG (Acetylene cutting torch with digital torch controller) |

☑ | ☑ | E |

| 100196 | Linear drive cable, IHT 7500-2-901 (10 / 20 / 30 m) | ☑ | ☑ | F |

| 140525 | DIG Cable, RS485 (10 / 20 / 30 m) | ☑ | — | F |

| 140820 |

Operator Terminal APC (Tablet, RS485-USB converter) |

☑ | — | G |

ACCESSORIES

| Item No. | Description |

| 140522 | Heat Shield FIT+ three |

| 140551 | Splash Protector |

| F25910021 | Start Kit FIT+ three PMY |

| F25910022 | Start Kit FIT+ three A |

SPARE PARTS

| Item No. | Description |

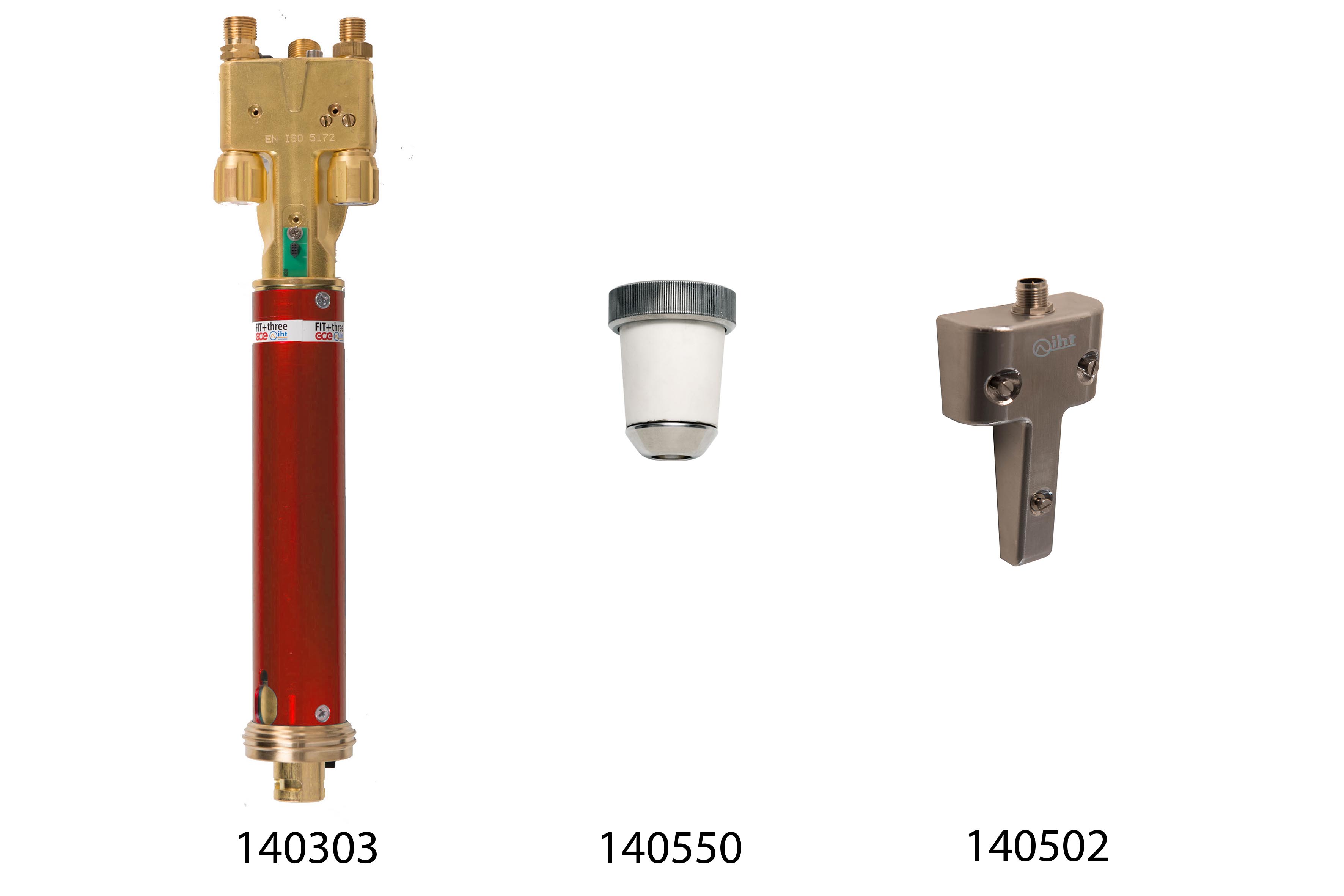

| 140303 | Cutting Torch FIT+ three 220/45PMY red (without torch controller) |

| 140304 | Cutting Torch FIT+ three 220/45A red (without torch controller) |

| 140502 | FIT+ three Torch Controller DIG |

| 140550 | FIT+ three Clearance Sensor Kit |

TOOLS

| Item No. | Description |

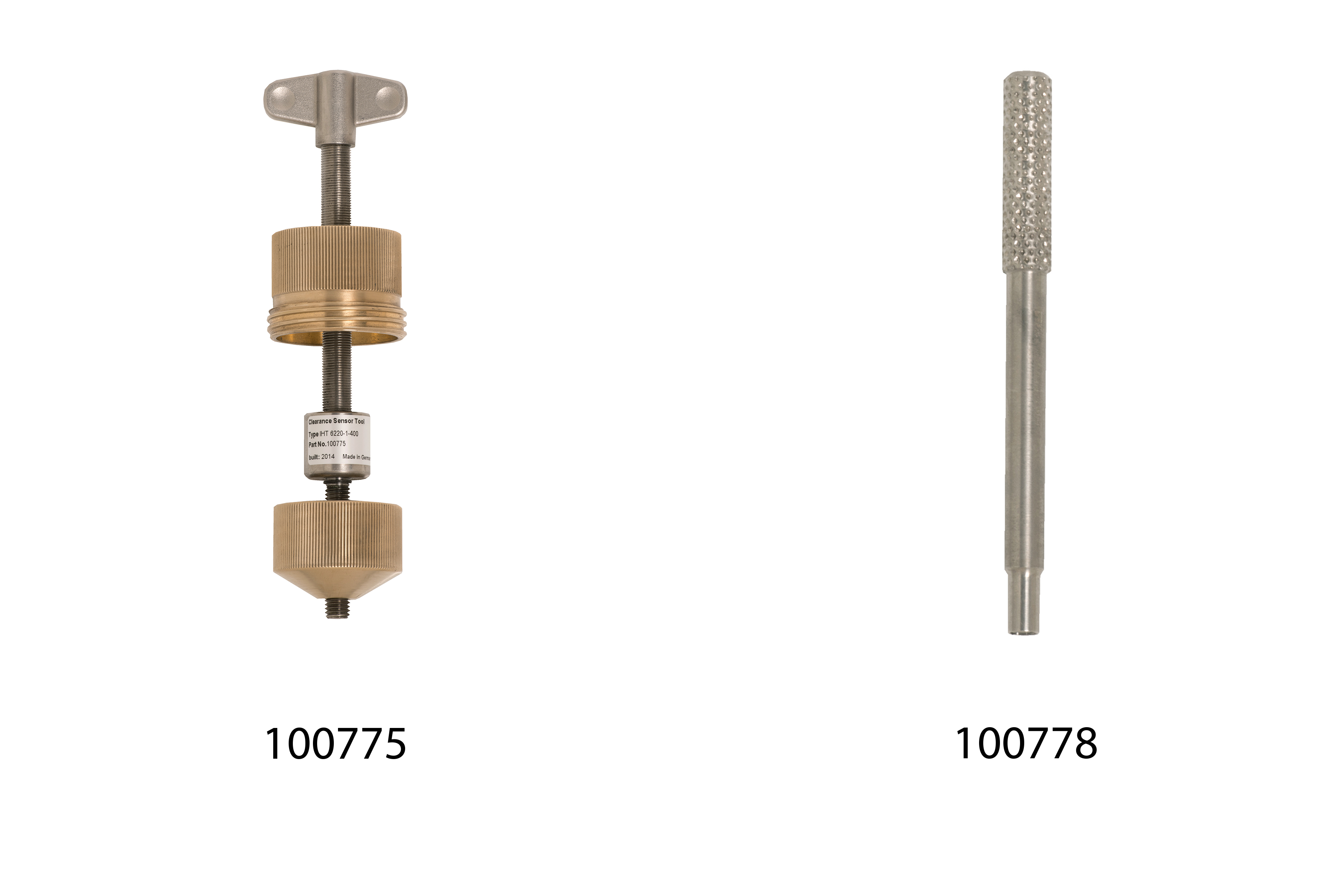

| 100775 | Clearance Sensor Tool |

| 100778 | Pin Tool |

CONSUMABLES

| Item No. | Description |

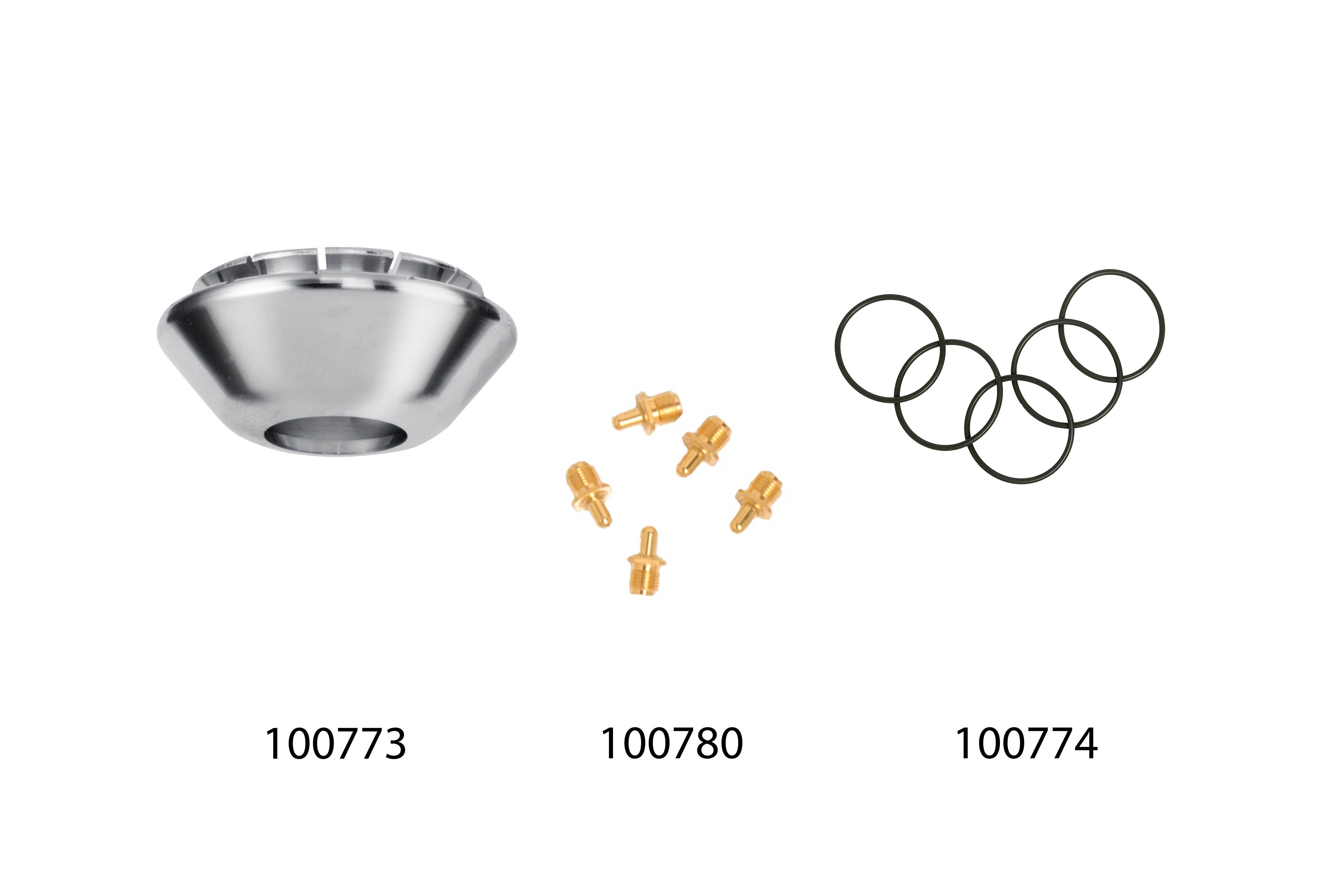

| 100773 | Clearance Sensor type B 14/19 |

| 100774 | O-Ring (5 pcs) |

| 100780 | Contact Pin (5 pcs) |

Descargas

Arriba

Descargas adicionales para este producto

Productos relacionados

Arriba

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_.jpg)

.jpg)