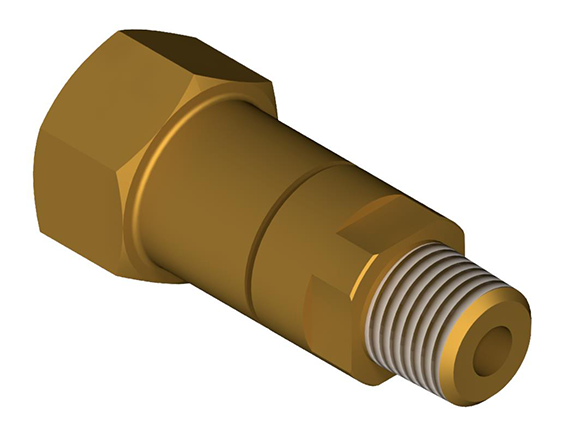

NON RETURN VALVE LOW AND MIDDLE FLOW SERIES

CV300 BG CHECK VALVE, FOR INDUSTRIAL GAS SUPPLY SYSTEMS, seat material brass/ceramics, 300 bar working pressure, brass

Used in pipelines, the CV300 BG prevents an undesirable flow in the opposite direction to the main flow direction.

Mounted in the high-pressure area of manifolds of industrial gas supply systems, the CV300 BG protects the compressed gas cylinders against transfer in the event of incorrect operation. The CV300 BG can be used in supply systems for inert, flammable and oxidising gases up to a gas quality of 4.5. The use of the check valve is not possible with corrosive gases or their mixtures.

SPECIAL FEATURES

The special seat seal and the use of selected gas-wetted parts allow the use with oxygen up to 300 bar working pressure. The Oxygen ignition test for non-metallic seat sealed check valves which is required during the development phase can be omitted with the CV300 BG due to targeted material selection.

- Compact design

- Designed and approved in accordance with relevant sections of EN ISO 10297:2015

- Specially cleaned

TECHNICAL DATA

| Working temperature: | -20°C to +60°C |

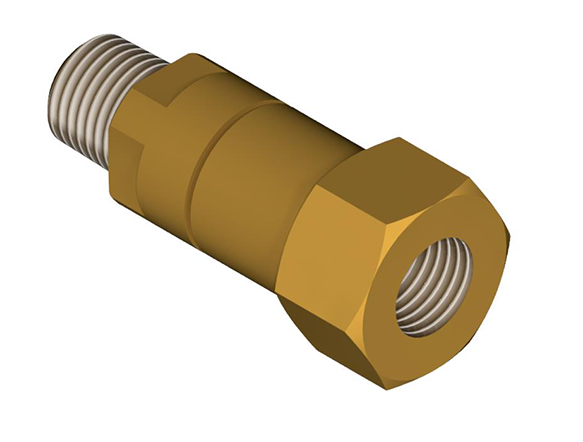

| Inlet connection: | NPT 1/4" female |

| Outlet connection: | NPT 1/4" male |

| Max. working pressure: | 300 bar |

| Length: | 54 mm |

| Weight: | 0,07 kg |

Télécharger les fiches techniques

Téléchargements additionnels pour ce produit